11-july-2022

A plasma and oxyfuel machine that lasts forever? - Maintenance tips and techniques

Can an oxyfuel and plasma machine last for many years? Sure. But for that, some care must be taken in its preventive maintenance. We’ll give you some tips.

What you will find in this article:

- Do I have to do preventive maintenance?

- Taking care of my plasma and oxyfuel

- The operator is a key part of preventive maintenance

- In short…

- MOTOFIL maintenance contract

Do I have to do preventive maintenance?

All machines need preventive maintenance to prevent serious problems and increase longevity.

This process consists of carrying out maintenance tasks that aim to prevent and avoid problems that cause a reduction in performance and can generate large losses.

Other main reasons are:

- Minimize the possibility of unforeseen interruptions or major breakdowns;

- Ensuring the operator’s safety;

- Have the machine always usable;

- Achieve maximum productivity.

Taking care of my plasma and oxyfuel

In preventive maintenance, the equipment goes through processes of cleaning the machine, lubricating components, complete overhaul of electrical and mechanical systems and checking consumables and peripherals.

Consumables

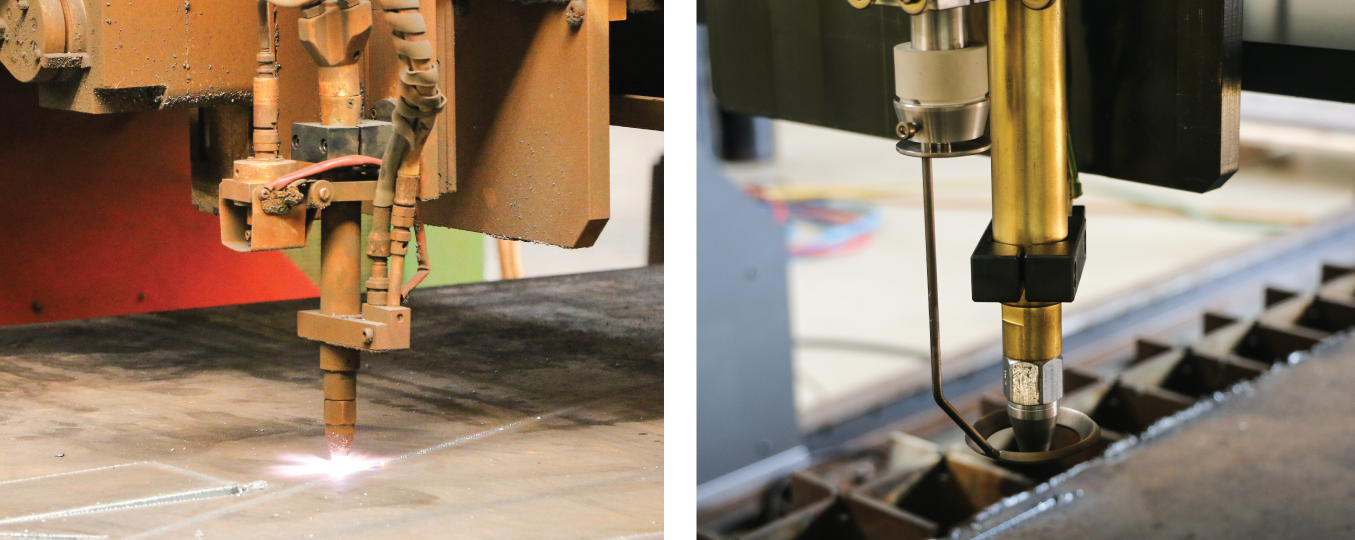

Before starting to use the machine, check the wear level of the consumables. In case they are very worn, the machine will hardly be able to make the cut, be it plasma or oxyfuel.

If, for example, you notice that there is roughness in the cut or any other anomaly, you should stop the machine immediately and change the consumables.

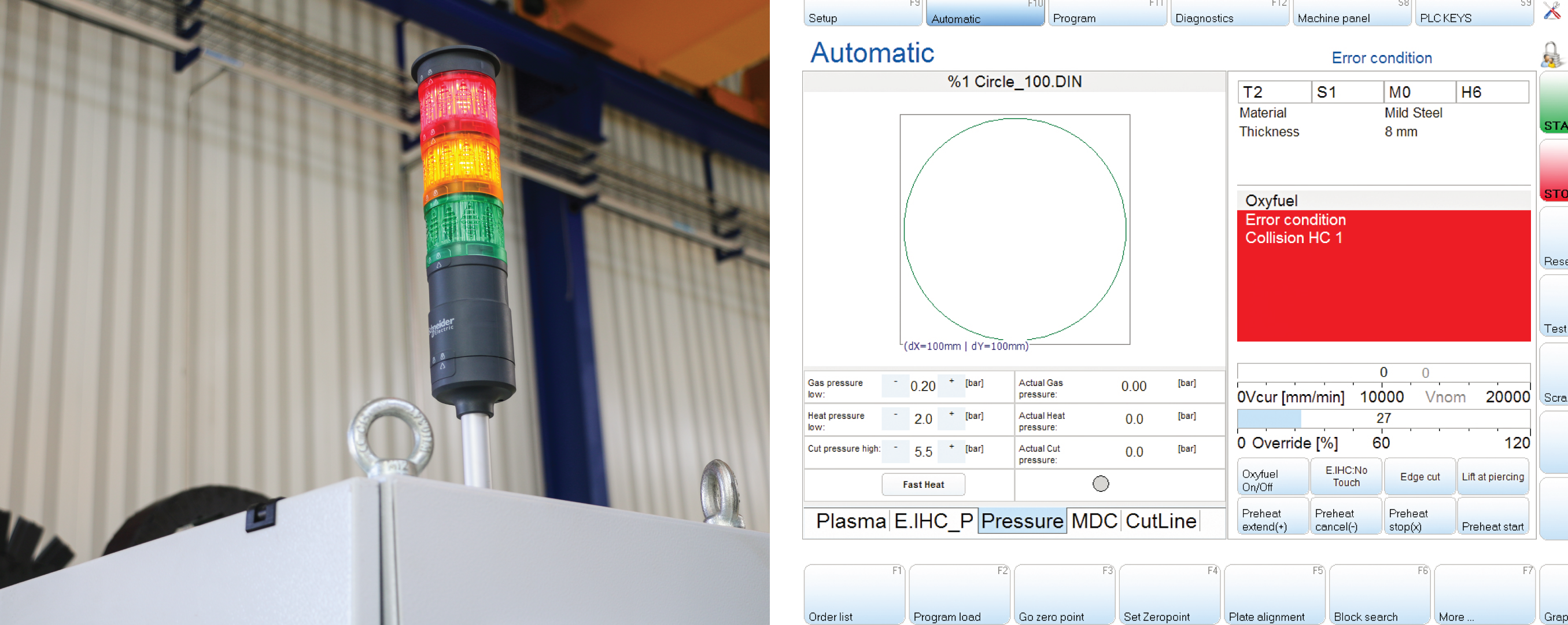

In the case of Motofil's plasma and/or oxyfuel cutting machines - DRAGOm -, whenever an anomaly is detected, the machine will give an error signal, displaying an error signal on the machine's control panel and turning on the machine's lights.

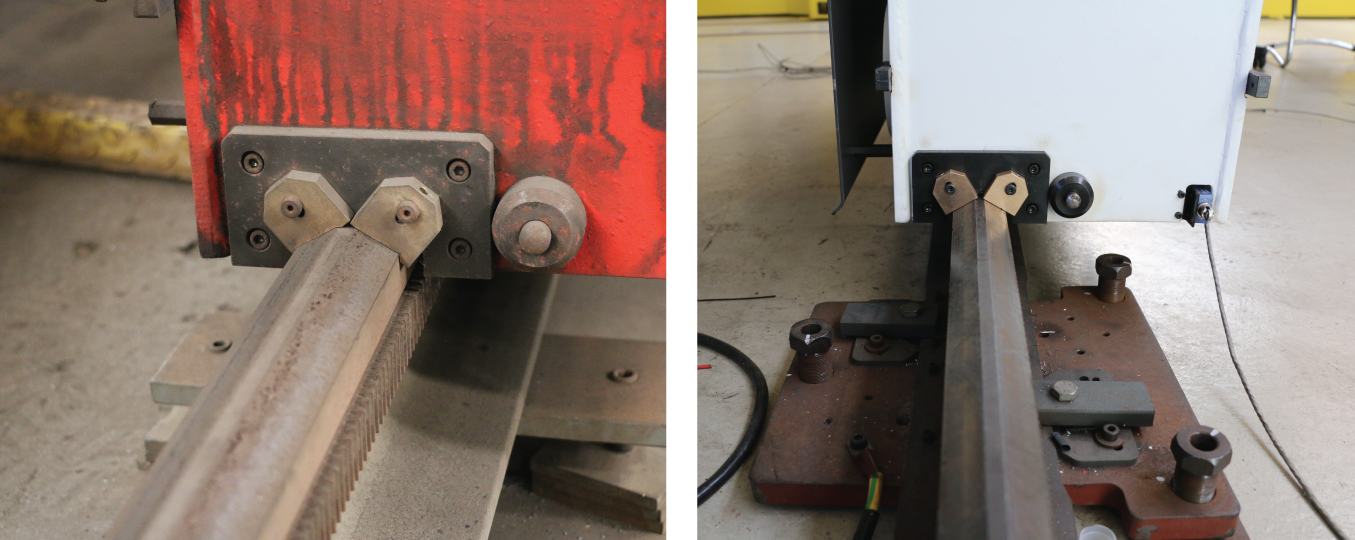

Insert Drills Bits

When drilling, the main consumables to check are insert drill bits, which can get damaged.

To identify that the bits are damaged, the operator must be aware of the machine, both visually and audibly. When the insert drill has worn out consumables, it will no longer be able to drill and will stop working.

Gantry

In addition to consumables, the machine operator must pay attention to the Y axis displacement skates and must clean the guides and lubricate them regularly. The X-axis rail scraper should also be checked to avoid accumulating dirt on the wheels.

Table cleaning

Periodic inspection of the suction gates should be carried out along the entire table, to detect damage that compromises the suction efficiency.

There are also other floodgates that must be checked and, if damaged, will have to be repaired or replaced.

The cutting table is made up of a blade holder and rulers, which is one of the most “sacrificed” areas of DRAGOm. There are cases where slag accumulates all over the table and its deposits end up being completely full.

Cartridges and Aspiration Filters

Cartridges tend to accumulate a huge amount of dust, depending on the machine's workload.

As a rule, and depending on the volume of work, they will need to be checked and cleaned weekly, and the cartridge must also be rotated 180º.

When its wear becomes too high, the pressure of the machine drops and it shows an error signal on the control panel, so it must be replaced.

The suction filters, in turn, must be changed after one year or after 1500 working hours.

Electrical Panels

Electrical panels, depending on the type of industry and volume of work, must be cleaned to ensure that the dust generated by cutting does not affect their performance. In a metalworking company that has a considerable amount of work, for example, at least a weekly cleaning of the boards is recommended.

Height Sensor

Attention should be paid to the height sensor (ring) of the oxyfuel unit, which, when damaged, no longer controls the height properly.

When this happens, the oxyfuel torch does not rise and the height sensor must be replaced immediately.

The operator is a key part of preventive maintenance

The operator must listen and pay attention to machine signals.

For example, when detecting the wear of consumables, he must pay close attention to the behavior of the machine and, if he detects any anomalies, immediately check the consumables.

These are the essential precautions to ensure greater longevity of the machine:

- replacement of consumables;

- regular cleaning of slag deposits;

- cleaning of filters and electrical panel;

- lubrication and cleaning of the displacement skates (Y axis) and the rail scraper (X axis);

- cleaning of the cutting table and its deposits.

However, a machine of this magnitude will always need a more in-depth review, carried out by specialized technicians.

Motofil has a maintenance service available with a 3-year contract, which offers the customer an official diagnosis of the machine's condition. To find out everything about our maintenance contracts, contact our technical assistance service.

--

Related articles:

/ N/D